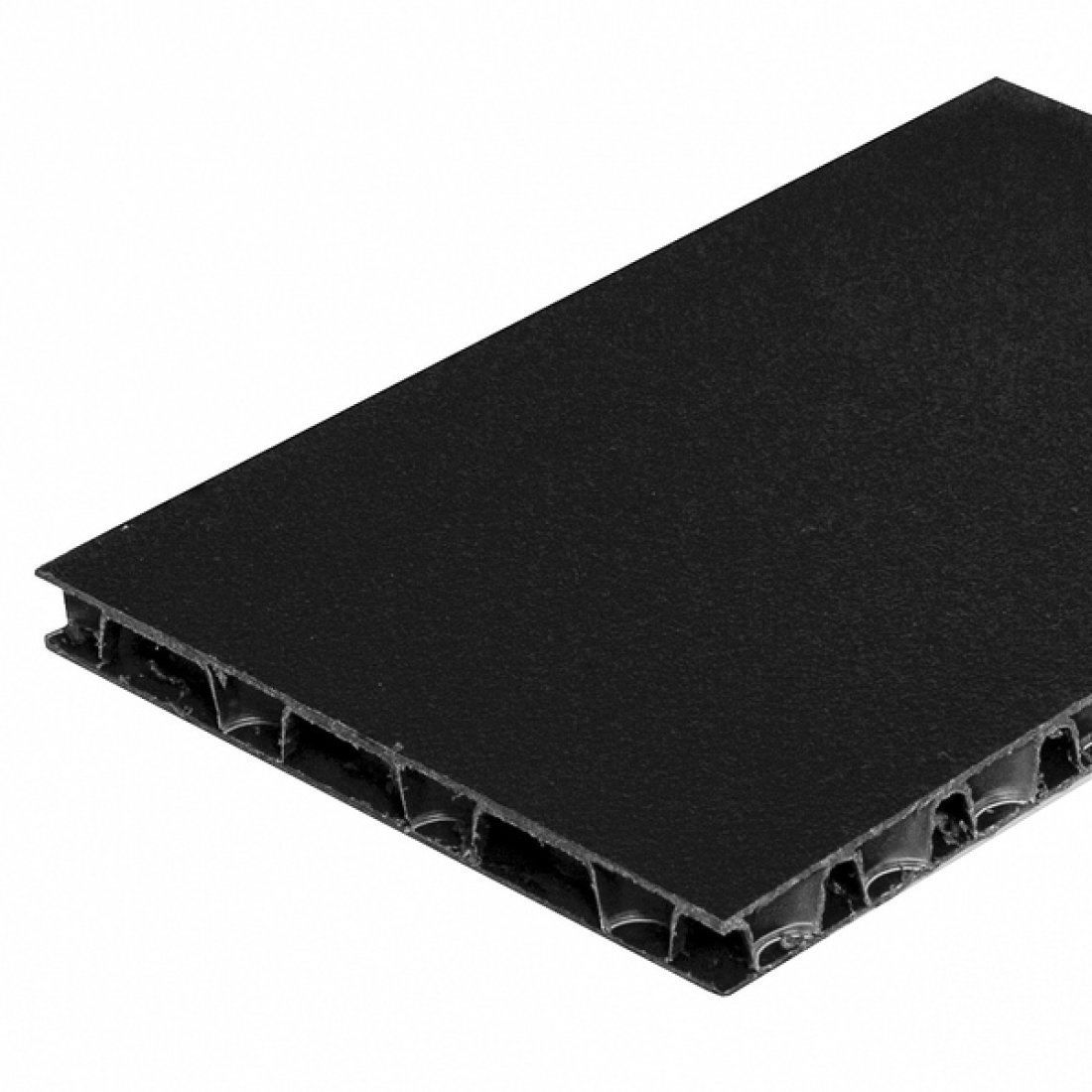

This then means you might as well use vac. It has no stiffness on its own, so at least one side must be laminated on the table. Because I had some non perforated pvc, but all my M foam was perfed for wet baggin.įoam is really a lot more work John. So, the deck shoe has a bit of pvc if you look close. It was going to be all M except I had to hand laminate the deck shoe. If you look at the background of my pictures you'll see a Gurit M foam Gurit pvc hybrid. Sorry for the repeats and grammar.no time to edit firtherįor that Wharram, stick with ply John. But you do pay in resin and that means weight, too. The cost of a one inch piece of plascore 5x10 is about 1/3rd the cost of Gurit M foam. The great advantage I have found is you can buy it in 5x10' sheets. A place it would actually be nice in your build is cockpit base or decks. The veil requires a wetout greater than foam cores. It is also cheap up front, but resin thirsty in hand layup. But for a Wharram hull, as a builder, no. I built my cat cabin bottom and sole with it and cockpit panels. All of the raw, exposed edges of honeycomb must be cored with something different. I can tell you that the build time for plywood is at least 1/2 that of polypropylene honeycomb, probably more. See how we had to dog it in to glue on the high density for fastenings? Then squeezeout, then sanding squeezeout, then prefilling before glassing.Īlik is the expert. This is a lot of extra work raw edges of honeycomb are no good just like ply.sort of. Here a catamaran cabin bottom with panel widths wider than 4'. I wanted these pics as post scripts (wouldn't place at end?), but basically polypropylene honeycomb has some pluses in certain parts of a build.

0 kommentar(er)

0 kommentar(er)